Cut-Resistant Gloves 101: What You Really Need to Know

Did you know that over one-third of workplace hand injuries are caused by cuts? The good news is that most of these injuries are preventable with the right gloves. The challenge is knowing which gloves are right—because not all cut-resistant gloves are created equal.

With so many materials, ratings, and styles on the market, glove selection can feel overwhelming. Let’s simplify it and focus on what actually matters.

🔪 How Do Cuts Happen?

Understanding how cuts occur is the first step toward choosing effective protection. Most cut injuries fall into two categories:

Push Force

This happens when a sharp object presses directly into the hand—such as handling metal edges, glass, or sharp components.

Pull Force

This occurs when a blade or sharp surface slides across the hand, creating a slicing action.

The most effective cut-resistant gloves are designed to help protect against both push and pull forces, reducing the likelihood and severity of injury.

🧵 Materials That Make the Cut

Different glove materials provide different levels of cut resistance, comfort, and durability. Common options include:

- HPPE (High-Performance Polyethylene): Lightweight, flexible, and comfortable. A popular choice for general industrial applications.

- Para-Aramid (e.g., Kevlar®): Naturally heat-resistant and durable, making it ideal for higher-temperature environments.

- Metal Mesh (Chainmail): Extremely cut-resistant and commonly used in food processing and knife-handling applications.

- Composite Yarns: Engineered blends (often HPPE with steel or other fibers) designed to achieve higher cut levels while maintaining dexterity.

Choosing the right material depends on the hazard, not just the cut level.

📏 Gauge and Coatings: What’s the Deal?

Glove Gauge

Gauge refers to the thickness of a knit glove:

- Higher gauge = thinner glove, better dexterity

- Lower gauge = thicker glove, more durability

There’s always a balance between protection and precision.

Palm Coatings

Palm coatings don’t significantly increase cut resistance, but they dramatically improve real-world performance by enhancing grip and extending glove life. Common coatings include polyurethane (PU), nitrile, latex, and PVC—each suited to different environments.

🛡️ Understanding Safety Standards

Cut-resistant gloves are tested to ensure they provide the protection they claim. The two most common standards are:

- ANSI/ISEA 105 (North America): Rates gloves from A1 (lowest) to A9 (highest) based on gram-force cut testing.

- EN 388 (Europe): Uses the Coup Test (levels 1–5) and the ISO 13997 test (levels A–F).

Always confirm which standard a glove is rated under and ensure it aligns with your workplace requirements.

🚫 Common Misconceptions

“Cut-Resistant” Means “Cut-Proof”

No glove is completely cut-proof. Cut-resistant gloves reduce risk—they do not eliminate it.

Leather Equals Cut Protection

Leather alone is not cut-resistant. It must be paired with a cut-resistant liner to provide meaningful protection.

All Gloves Offer 360° Protection

Most standards test only the palm area. If full-hand protection is required, look for gloves specifically labeled as 360° cut resistant.

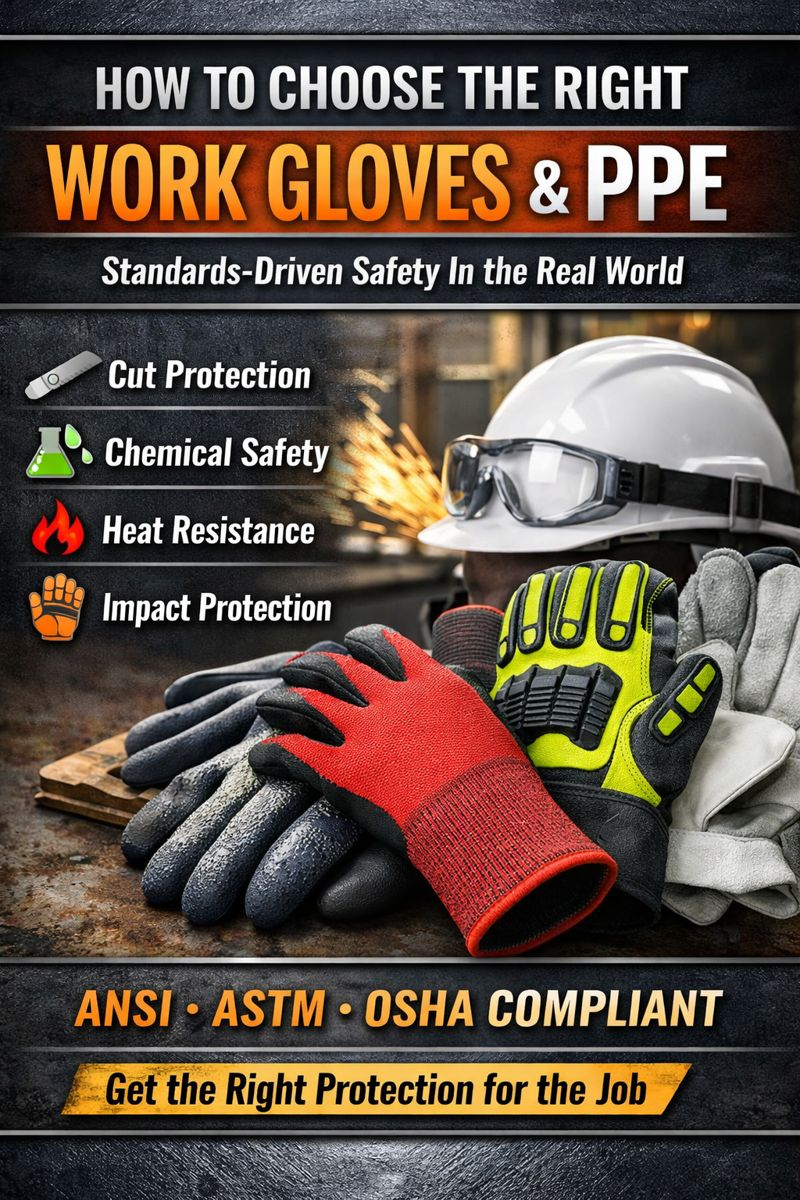

🖼️ Visual Aids Matter

Images, charts, and graphics—like cut-level comparisons and material breakdowns—can make glove selection much easier. When available, visual aids help translate test data into real-world understanding.

✅ Conclusion: Choose Smart, Not Just Strong

Choosing the right cut-resistant glove doesn’t have to be complicated. Start by understanding how cuts occur, match materials to the hazard, and always verify safety ratings under the correct standard.

The best glove is the one that:

- Matches the actual risk

- Meets verified safety standards

- Fits properly

- And gets worn consistently

When protection, comfort, and real-world performance align, hand injuries drop—and productivity improves.

Stay safe out there. 🧤