The Resource Centre:

Your Hub for Safety Knowledge & Product Support

Frequently

Asked Question

How do I choose the right glove or PPE for my application?

Document the process of the application you are picking gloves/PPE for and list in priority order the hazards that are present and require protection against. Once you have established this description and listing, discuss these with your Stalwart Safety Representative to assess the characteristics required to provide the protection needed while understanding the functions of the application. We will get you the best cross-section of protection, application and comfort for your workers.

What do cut resistance levels mean and how are they tested?

ANSI/ISEA 105 cut resistant standards use a simple scale (A1 to A9) to make it easy to understand how much protection a glove offers against cutting hazards in practical work settings. The higher the number, the more resistance the glove provides against being sliced by sharp objects like blades or glass.

Practical Explanation

A1 gloves are for light tasks like handling paperwork or small objects—think of them as light-duty gloves, since they only protect against about 200 grams of cutting force.

Levels A2 to A3 work well for jobs with moderate cut risks like assembly, light construction, or handling plastics.

A4 to A6 gloves are good for more hazardous jobs, such as working with sheet metal, cutting tools, or glass, where the chance of cuts is noticeably higher.

The highest ratings, A7 to A9, are intended for the most dangerous tasks, such as rescue operations, glass manufacturing, and working with very sharp blades—gloves at this level withstand up to over 6,000 grams (more than 13 pounds) of cutting force.

How the Ratings are Set

A glove’s cut rating is determined by a lab test where a machine pushes a blade across the glove material with increasing pressure until it slices through—then the amount of force needed (measured in grams) decides its ANSI score. The result makes choosing gloves very straightforward: the higher the cut rating, the more protection you have in real-life scenarios.

For everyday guidance, engage with your Stalwart Safety Representative to describe the application/operation where protection is required so that we can translate this information into the correct level of protection for your environment.

Can you help me meet industry compliance standards (ANSI, OSHA, CFIA, FDA, NFPA, etc.)?

Yes, our team can help you meet industry compliance standards including ANSI, OSHA, CFIA, FDA, NFPA, and more.

We provide expert guidance on selecting PPE and safety equipment that aligns with current regulatory requirements for your workplace, including specific ANSI and OSHA standards for hand, eye, and body protection.

Our products are clearly marked with compliance information, helping you choose items that match your required standards—whether you work in manufacturing, food processing, healthcare, or industrial environments.

We stay up-to-date with evolving regulations so you can be confident your safety solutions meet applicable standards for health and worker protection.

Support is available to assist with compliance documentation and hazard assessments so you can achieve best practices and regulatory approval in your field.

Can I get customized PPE for my workforce?

The simple answer is yes. The longer answer is we need to understand your needs for protection, the types of hazards present, number of employees to protect, economic feasibility of custom protection, and ultimately your participation in developing a custom product. Stalwart Safety will dispatch a PPE Expert to assess the needs, take any and all measurements

Do you design women-specific gloves or PPE?

Stalwart absolutely designs women-specific PPE including garments, gloves & hand protection to provide a better fit for increased safety and adoption as well as range of motion in use.

What coating should I choose for my gloves?

Selecting the right glove coating for industrial applications involves understanding the specific work environment, risks, required protection, and user needs. The following questions help guide the process:

What type of substances will the worker handle (wet, dry, oily, chemical)?

What hazards are present (abrasion, cuts, punctures, chemicals, heat)?

What level of grip and dexterity is required for the job?

Will the gloves need to function in cold or hot conditions?

Are there worker sensitivities (such as latex allergies) or hygiene requirements?

Is the glove for general use, or does the application require specialized protection (e.g. electrical, heavy machinery)?

Process for Choosing the Best Glove Coating

Assess the physical and chemical hazards present in the workplace, including the tasks to be performed and materials handled.

Identify the environmental conditions—will gloves be exposed to wet, oily, or dry environments? This often determines coating material. For example, nitrile performs well in oily settings, while crinkle latex offers superior grip in wet conditions.

Match the grip, dexterity, comfort, breathability, and flexibility required for the task to the glove’s coating attribute.

Polyurethane is ideal for fine assembly where touch and flexibility are important.

Nitrile Coatings are excellent for dry and oily grip with various styles of Nitrile Coatings available.

Latex Coatings are good for non-oily grip and excellent for non-textured surfaces such as glass.

PVC coatings are better for handling adhesives and cold resistance.

Consider any allergies or sensitivities such as latex, and select alternative materials as needed.

Ensure that chosen gloves comply with industry safety standards (ANSI, OSHA) and are suited for any unique sector requirements.

Test gloves in practical use to confirm suitability before full deployment; adjust based on worker feedback and operational results.

Ask your Stalwart Safety Representative to discuss your applications/operations or better yet have them visit your facility to do a proper hand protection assessment.

What is the difference between ANSI & EN388 standards?

The main differences between ANSI/ISEA 105 and EN388 glove standards are:

ANSI/ISEA 105 (U.S.) uses a 9-level (A1-A9) cut resistance scale based on grams of force (TDM test), while EN388 (Europe) uses two cut resistance methods (Coup and TDM) rated as levels A-F.

ANSI 105 provides more granularity for high-cut-resistance gloves, while EN388 covers lower to medium ranges and includes both methods for high cut.

EN388 rates gloves for abrasion, cut, tear, and puncture resistance; ANSI/ISEA 105 covers abrasion, cut, and puncture (plus chemical and heat resistance for some gloves).

The scoring systems differ: ANSI rates abrasion resistance from 0-6 and puncture from 0-5; EN388 uses a scale of 1-4 or 1-5 for these properties.

EN388 uniquely includes impact resistance, whereas ANSI/ISEA 105 does not rate for this property.

Does Stalwart Safety do PPE Audits to help us develop a proper PPE Program?

Absolutely, Stalwart Safety often does PPE Audits, especially as it pertains to hand, arm and body protection. Our PPE Audits entail a comprehensive in-person plant visit/tour identifying hazards and doing risk assessments vs. application by area or operation so that it is as tailored to the operations as necessary. A comprehensive report is developed to identify the PPE to be selected for trials to match recommended standards. Trials will be staged to gain feedback and make any adjustments or customization in the PPE recommended followed up by training and usage monitoring to educate your employees. Lastly, finalization of PPE chosen, with inspection & maintenance procedures (if necessary) being documented.

Do you sell directly to end-users?

Stalwart does NOT sell directly to end-users, we only sell through approved distribution channels. We do, however, engage with end-users in order to work to create solutions that solve industry-wide problems through direct understanding of the application, hazards and how workers are using the PPE. Once product is developed, we will support its use through a Stalwart approved distributor.

Additional Resources/Information

Articles

Browse safety articles and reference material selected by Stalwart Safety.

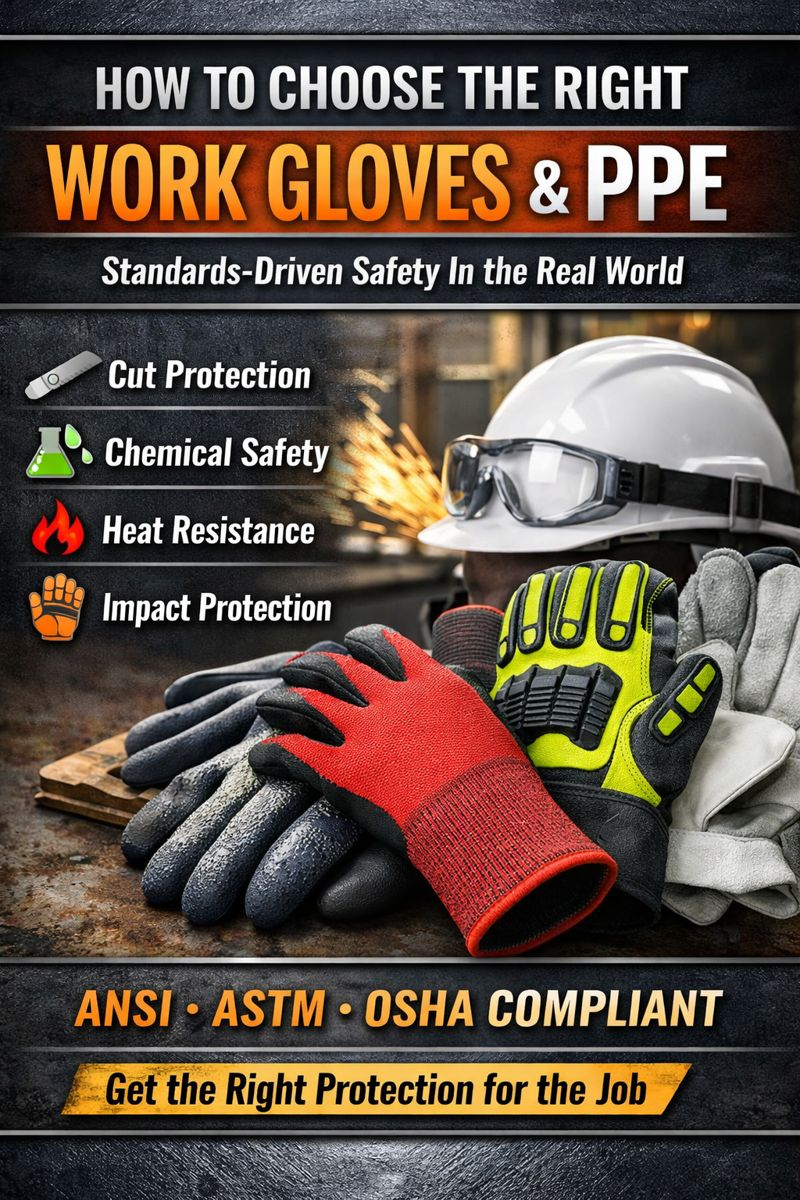

Infographics

Quick visual references to help communicate safety standards and best practices.

Presentation Decks

Download training decks and educational presentations for internal safety meetings.

Stalwart Safety Blog